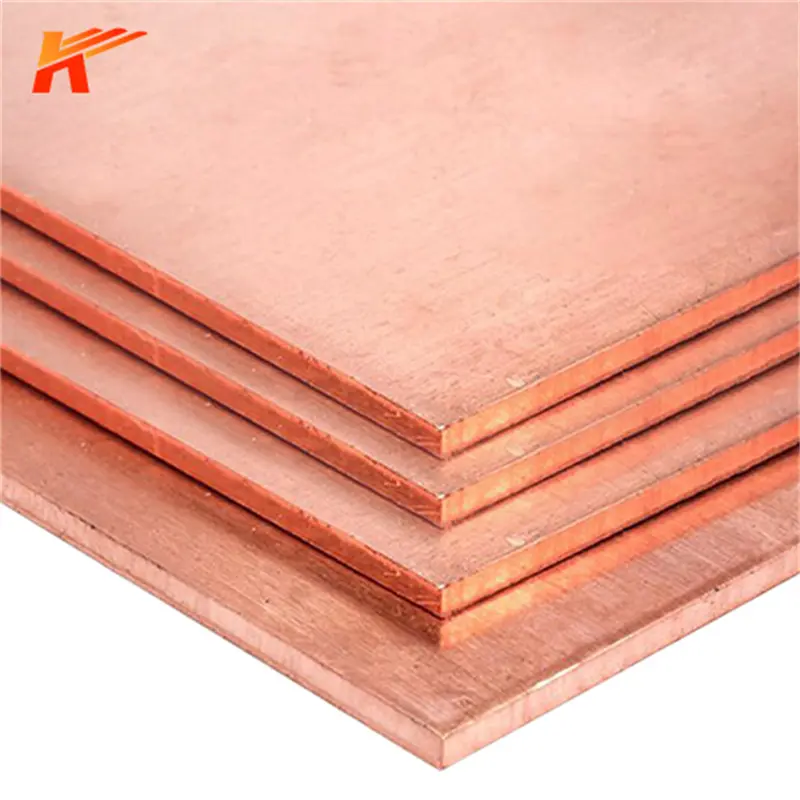

Letlapa la koporo ke mofuta o ka sehloohong oa lisebelisoa tsa koporo.E na le thepa e phahameng ea 'mele, conductivity e ntle haholo, phetisetso ea mocheso, ho hanyetsa kutu e ntle haholo, ts'ebetso ea electroplating, welding ea fiber, le sebopeho se setle le se setle sa tšepe le boleng bo holimo. indasteri e nang le mefuta e fapaneng ea boenjiniere bo fapaneng, libetsa tsa lapeng le lisebelisoa.

ke mofuta o ka sehloohong oa lisebelisoa tsa koporo.E na le thepa e phahameng ea 'mele, conductivity e ntle haholo, phetisetso ea mocheso, ho hanyetsa kutu e ntle haholo, ts'ebetso ea electroplating, welding ea fiber, le sebopeho se setle le se setle sa tšepe le boleng bo holimo. indasteri e nang le mefuta e fapaneng ea boenjiniere bo fapaneng, libetsa tsa lapeng le lisebelisoa.

Mokhoa oa koporo o etsoa tjena:

1. Cold rolling-sawing mokhoa

Tshebetso ea tlhahiso ke: casting and heat-hot taver- (milling surface-opening-cold rolling-quenching-) Picky and passivation-batse-cold rolling-sawing Sekolo se paka ka ho otloloha-kena ka ntlong ea polokelo.Tšobotsi ke hore likarolo tsa ts'ebetso ea poleiti ea koporo li ka sebelisoa hantle, empa ho na le likhahla tsa moriri le li-crumbs tsa litšoantšiso, lithōle ha li na arc, bokaholimo ba bokaholimo ha bo boreleli, bophara bohle bo boholo, le melaoana e nepahetseng e phahameng. ha li kopane.Theko ea lihlahisoa e phahame.

2. Cold rolling-Lashen mokhoa

Ts'ebetso ea tlhahiso ke: ho lahla le ho futhumatsa-hot taver-milling surface-cold rolling-cutting strips-quenching and passivation-La Shou-cast and rolling schools straight-packaging-packaged- Kena ntlong ea polokelo.Tšobotsi ke hore mefuta eohle ea litekanyetso tsa boleng e ka fumana ts'ebetso e ntle le tlhahiso e theko e tlase, empa poleiti ea boronse e khaola mapheo 'me mamello ea boholo e ke ke ea sebelisoa.

3. Cold rolling mokhoa oa aluminium profile

Ts'ebetso ea tlhahiso ke: tšepe hlobo e khubelu ingot-hot (mofuthu) rolling-pickled passivation-rolled aluminium profile-quenching and passivation-refined aluminium profile-cast rolling school otlolohile litlhophiso tsohle tse tsitsitseng Nōka-packaging-e kena ka tlung ea polokelo.Tšobotsi ke hore litekanyo tsa ts'ebetso ea poleiti ea koporo li ka fumana ts'ebetso e ntle.

4. Ho penya ho bopa-Lashen mokhoa

Ts'ebetso ea tlhahiso ke: ho lahla le ho futhumatsa-ho peta molding-Lashen-quenching-pickling passivation-La Sulin-casting le likolong tse pota-potileng ka ho toba-ho paka-ho paka.Ts'ebetso ena ea ts'ebetso e eketsoa ka ho tima le ho khetha mokhoa o qaqileng ho netefatsa hore poleiti ea koporo e na le litšobotsi tsa 180 ° tse kobehang, 'me litekanyetso tsa boleng lia qhekelloa.Mokhoa ona o bonolo, o sebetsa hantle haholo, o na le bokhoni bo phahameng ba tlhahiso, empa theko ea sehlahisoa le eona e phahame haholo.

5. Ho qotsa (kapa boemo) Ho roala tšepe-ba batang ho roala-Lashen mokhoa

Ts'ebetso ea tlhahiso le tlhahiso ea moetsi oa boto ea koporo ke: holimo (kapa boemo) ho roala litšepe-tse batang-cold rolling-pickling passivation-Lashen-Laoshen-Casting le likolo tse pota-potileng laebrari ea ho kenya liphutheloana.Tšobotsi ke hore mokhoa ona o bonolo 'me theko ea sehlahisoa e tlaase.Leha ho le joalo, litekanyetso tsa ts'ebetso ha li betere ho feta mekhoa e meng.Litlhaloso li thibetsoe, ts'ebetso e tlase, le tlhahiso e nyane ea tlhahiso.

Nako ea poso: Oct-21-2022